Technical Support Services

• Technical Design

• Commissioning

• Ancillary Certification

• Technical Support

• Service & Maintenance

• Installer Training

• Estimation Service

• Expert Advice

• Professional Indemnity Insurance

• Assistance with SEAI Grant Application

All calculations are based on SR50-1-2021:Code of Practice - Part L - Domestic Plumbing & Heating

All calculations and data will be provided to the BER Assessor so compliance with regulations can be confirmed

The design provided is covered by Professional Indemnity if installed as per specifications based on the information provided.

Any changes in dimensions, U-Values will require the calculations to be amended.

We can also provide commissioning, design sign off and ancillary certification.

Service and Maintenance

Service and maintenance plans for your Panasonic heat pump are provided through our nationwide network of service engineers. Regular maintenance is required to ensure you get the maximum performance from your heating system and to extend the lifespan of your heat pump.

Annual servicing by a Panasonic trained professional is also required to fulfill the conditions of your heat pump warranty.

Underfloor Heating System Design

Our design team provide bespoke underfloor heating system designs and product specification with comprehensive under floor heating drawings indicating manifold locations, loop directions, loop lengths and cutting schedules.

Underfloor heating is an efficient way of providing warmth to a room without the requirement of radiators which take up valuable space. With underfloor heating, pipes are laid within the floor construction, and with warm water circulating the floor becomes one large low-temperature radiator. The underfloor heating system will only need to run a couple of degrees higher than air temperature to provide a comfortable warmth to a room. When the floor temperature is higher than the air temperature, the floor will release radiant heat. The heat output from the floor is directly related to the temperature of the floor and that of the surrounding air.Since the UFH system operates as a radiant heating system, it effectively reduces heat wastage at elevated levels by heating from the floor upwards.

The aim for UFH design is to create an even surface temperature across the floor area within a building which will ensure a uniform comfort level throughout the structure.

An UFH system can be set 1-2 degrees lower (ambient) than a conventional radiator system. This reduces waste heat at levels above head heights and in turn saving on fuel costs.

Underfloor heating offers many benefits to homeowners.

- It is an energy efficient method of heating particularly when combined with low temperature heat sources such as air to water heat pumps.

- As heat is distributed evenly and floors will feel warm underfoot this provides a comfortable living environment.

- Walls remain unobstructed by radiators giving greater design flexibility.

- As there are no sharp edges, obstacles or hot surfaces underfloor heating can be a safer option.

- Underfloor heating is a good choice for those with allergies as less air movement means less allergens are circulated.

Underfloor Heating Design Principles

Our engineers can provide heat loss calculations at the start of any UFH project in line with current building regulations. Upon receipt of relevant project specifications and floor plans, CAD/Revit technicians alongside our engineers will be able to complete relevant heating calculations for the UFH system. These calculations supply the specific heat outputs and flow rates for each UFH loop. To accompany these calculations we also provide UFH technical drawings identifying manifold locations, UFH loop directions, loop lengths and cutting schedules. This process prevents any wastage and facilitates a rapid installation. We offer a comprehensive system warranty which covers both individual componants and the entireheating system.

- UFH has a central distributions point, the manifold, which is serviced from the main heat source and distributes the hot water to the UFH pipes.

- UFH is operated with a low flow and return water temperature which means the systemworks efficiently with heat-pump technology.

- UFH uses the whole floor surface area as a heating medium, which takes away the conventional radiators and leaves the end user with more wall space.

Heat Outputs

The heat output achieved by UFH systems is a direct relationship between the difference in floor surface and room air temperatures. Many contributing factors determine the floor surface temperature such as floor construction, floor covering material, pipe size, pipe spacing and the temperature of the water circulating through the UFH pipes. In line with current building regulations it is rare for a new build to require outputs greater than 35-40 W/m2 based on a 20°C internal design temperature. to, achieve an acceptable temperature underfoot, BS EN1264-2 states that the maximum floor surface temperature is 9°C above the room temperature in occupied areas and bathrooms. This results in a maximum floor surface temperature of 29°C in occupied space with a room temperature of 20°C. A 9°C temperature difference will equate to a floor heat output of 100W/m2.

UFH Pipe Layouts

UFH Pipe Spacing

Several factors affect pipe spacing, such as size, heat source, and the chosen Polytherm Underfloor System.

For domestic use the most common scenario is 16mm pipe at 150mmc/c with a heatpump as the heatsource. In this case, tighter pipe centres will allowfor lower hot water temperatures and results in improved efficiency and lower energy costs.

For a commercial UFH project the pipe may be increased to 20mm pipe and 300mm c/c depending on the scope of the project, primary flow temperatures and floor build up.

Pipe Layout

There are a number of different ways to lay the pipe within a room, some patterns are meander, double meander and spiral methods. The most common of these are the meander and spiral. Where possible, the pipe should be laid so that the flow direction is to the coldest area of the room first, e.g. under windows, along outside walls.

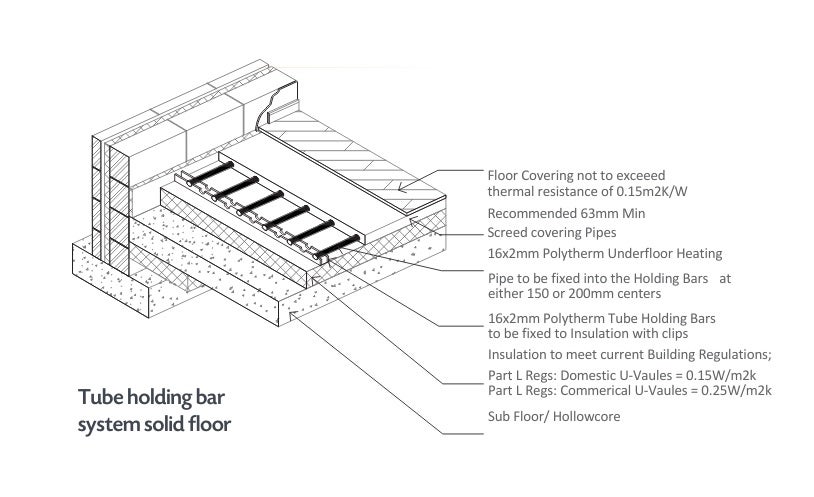

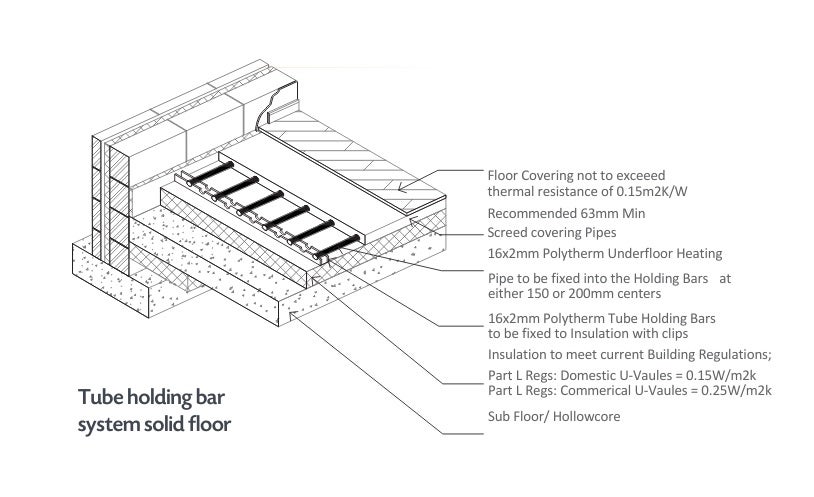

Technical designs showing typical floor layout

Floor Build-up

The thermal resistance of the finished floor covering also has to be considered in the design of the floor build-up. The floor supplier will have this information. It is recommended that the max thermal resistance does not exceed 0.15m2K/W.

Floor build-ups must meet the standards of the relevant building regulations. The relevant Building Regulations that must be adhered to are the Technical GuidanceDocuments Part L - Conservation of Fuel and Energy - Dwellings (2022).

Heating Controls

Our comprehensive range of thermostats offers different levels of control from a standard room thermostat controlling a single manifold all the way up to Wi-Fi enabled programmers allowing complete control of the temperature in each room in the house and offering remote access to your System whenever you need it.

Heating Controls Overview

Heat Merchants stock all leading brands of heating controls with options to suit every project and budget. We have categorised a

range of controls to provide a simple overview but a variety of additional options and brands are also available.

BRONZE

Single room thermostat controlling each manifold through a motorised valve. This is a very cost effective option but offers a limited level of control.

SILVER

A non-programmable room thermostat in each room controls each zone through actuators mounted on the manifold. This allows for individual room control but has limited additional control.

GOLD

A Digital touch-screen programmer provides greater controls and allows you to set both time and temperature in each room. Set back function as standard.

PLATINUM

Programmer allowing time and temperature control in each room,

set back function as standard. These units can also be controlled remotely via an APP (Internet Hub required)

Water Temperature Control

To ensure that the UFH system stays within its bounds we provide a mixing station, integrated with a pump to be placed at each manifold. This mixing station combines the primary heat source flow water temperature with the UFH return water temperature, resulting in a suitable flow temperature for the UFH system.

The Polytherm Underfloor Heating Mixing Station has a thermostatic mixing valve included which ensures accurate temperature control of underfloor heating. The unique design of the internal mixing valve components ensures that hot water from that heat source and return water from the underfloor circuit are mixed together in the valve components ensures that hot water from the heat source and return water from the underfloor circuit are mixed together in the valve body to produce a temperature range of between 20°C and 70°C (recommended to limit the flow temperature to the underfloor heating to max 50°C to protect the screed and finished floor). This temperature range will suit a wide range of underfloor heating applications, from commissioning new floor screeds to operating with very thick floor screeds in commercial applications.

The Compakt bathroom furniture series is innovative in design with a unifying simplicity and elegance. This collection offers several alternative styles including the innovative floating vanity with integrated washbasin. The Compakt range can be combined with furniture base units to provide additional bathroom storage.

Timeless straight lines and minimalist style combined with functionality and convenience characterise the extensive Spirit bathroom furniture range from Salgar. The choice of colours, sizes, basin styles and handles make this an exceptionally versatile bathroom solution.